Water Retaining Bodies

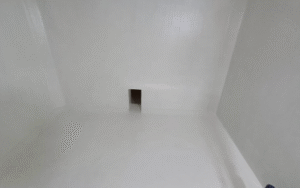

Structures that store or transport water—like swimming pools, reservoirs, potable water tanks, sumps, overhead tanks, sewage treatment plants (STPs), and dams—are constantly exposed to hydrostatic pressure, chemicals, and temperature fluctuations. Over time, these factors can lead to structural degradation and water leakage.

WG Group offers high-performance waterproofing systems specially designed for water-retaining structures, ensuring long-lasting water tightness, chemical resistance, and compliance with potable water standards.

Where Water Retaining Body Waterproofing is Recommended

- Swimming Pools

- Potable Water Tanks (Overhead and Underground)

- Sewage Treatment Plants (STPs)

- Rainwater Sumps & Collection Tanks

- Dams and Canals

- Ponds and Artificial Water Features

- Industrial and Chemical Water Storage Systems

Key Features of WG Water Retention Solutions

- Withstands Constant Water Pressure

- Resistant to Chlorides, Chemicals, and Wastewater

- Suitable for Potable Water Contact

- Active Self-Sealing Technology (Crystalline Systems)

- Flexible Crack-Bridging Systems (Elastomeric)

- Durable, Non-toxic, and Low Maintenance

WG Group Recommended Systems

- Withstands Constant Water Pressure

- Resistant to Chlorides, Chemicals, and Wastewater

- Suitable for Potable Water Contact

- Active Self-Sealing Technology (Crystalline Systems)

- Flexible Crack-Bridging Systems (Elastomeric)

- Durable, Non-toxic, and Low Maintenance

1. Cementitious Coating Systems (Positive Side)

A) Crystalline-Based Cementitious System

Active waterproofing using crystalline technology

Reacts with moisture to form insoluble crystals that seal capillaries and hairline cracks

Allows vapor permeability (lets concrete “breathe”)

Long-term durability and reactivation on water contact

Ideal for reservoirs, tanks, water treatment plants, and below-grade structures

Approved for potable water use

Surface Preparation Highlights:

All honeycombs, cracks, and joints sealed using crystalline mortar

Pressure grouting at weak zones using PRAH (for hydrostatic conditions)

50×50 mm angle fillets with PMM at all corners

Bore packing with non-shrink grout (e.g., GP2)

Surface must be in SSD (Saturated Surface Dry) condition

Post-Treatment:

Keep surface damp for 10 days

Protect from direct sun, wind, and frost using poly sheets or damp burlap

B) Polymer-Based Elastomeric Cementitious System

Flexible, elastomeric cementitious coatings

Protects against acid gases, chloride ions, oxygen, and water

Suitable for new and old concrete, brick, and blockwork structures

Seamless waterproofing for tanks, reservoirs, culverts, roofs, and basements

Crack-bridging capability for surface defects

Ideal as undercoat (not UV stable)

Surface Preparation Highlights:

Clean and patch all voids with PMM or non-shrink repair mortar

Grouting with PRAN (for non-hydrostatic conditions)

50×50 mm angle fillets with PMM

Bore packing with GP2

SSD condition required before application

2. Bitumen/Epoxy-Based Systems (Special Applications)

Used in STP tanks or potable water tanks where internal plaster cannot be removed

Applied only if the plaster is sound and well-bonded

Suitable for selective cases where direct access to concrete is restricted

Why Choose WG Group

- IS-standard & certified waterproofing systems

- Safe for potable water contact

- On-site expert inspection and customized system selection

- Detailed surface preparation protocols for guaranteed performance

- End-to-end execution and post-application support